Roll Forming Line for making Corrugated Iron Sheets / Roofing Sheets

| Sinusoidal / Wave Profile Corrugated Sheets | Trapezoidal / IBR Profile Corrugated Sheets | Duplex Machine for Sinusoidal and Trapezoidal Profiles |

Sinusoidal / Wave Profile Corrugated Sheet Making Machine

Summary of the Roll Forming Line Components:

-

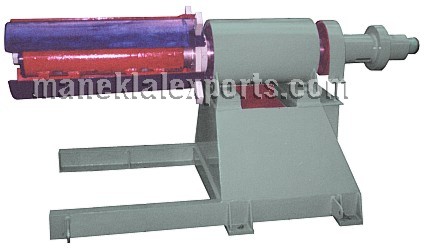

Uncoiler

-

Single head, 4-leaved design.

-

Coil expansion/collapse via a screw mechanism.

-

The shaft is inserted into the coil and tightened.

-

The shaft is mounted on a bush block and rotated by the pinch roll.

-

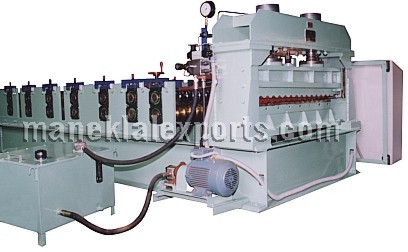

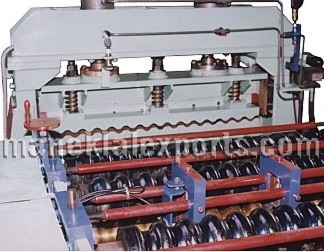

Roll Forming Machine

-

Comprises 17 forming stations.

-

Used to form corrugations in the sheet.

-

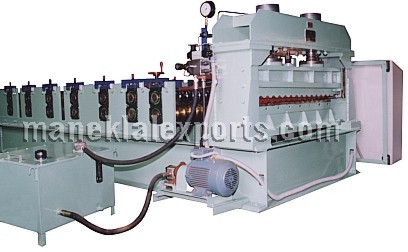

Hydraulic Cut-Off Machine

-

Uses a hydraulic cylinder to drive the shear slowly.

-

Shear consists of a fixed lower knife and a moving upper knife.

-

Sheet is clamped with a spring-operated clamp during cutting.

-

Hydraulic unit includes:

-

Hydraulic pump and AC motor on a steel tank base.

-

Oil filter, filler cap, oil level indicator, supply/return flanges.

-

Control station includes pressure gauge, valves, and piping.

-

Control Cabinet

-

Contains control panel for both hydraulic and forming machines.

-

Includes limit switches, emergency stop, and electric cables.

-

Functions:

-

Start/stop the forming machine.

-

Start/stop the hydraulic power pack.

-

Control the hydraulic cylinder for the cut-off machine.

Specifications:

Decoiler

Model:

DC-1

Capacity:

8 Tons

Shaft Diameter:

175 mm

Net / Gross Weight:

3100 / 3500 kg

Case Dimension:

2700 x 1300 x 1500 mm

Roll Forming Machine

Model:

RFM-1250

Corrugation Type:

Pitch 76.2 +/- 1 mm; Depth 18 +/- 1.5 mm

Forming Roller Stations:

16 Stations

Forming Roller size:

150 mm (for soft quality sheet)

Forming Speed:

12 meters / min

Motor:

10 HP

Capacity Width:

1000 to 1250 mm

Capacity Length:

up to 9999 mm (optional piler table required

for maximum length you wish to produce)

Material of Sheet:

Soft Quality (Annealed) Galvanized Sheet

Sheet Thickness:

0.3 to 0.7 mm

Net / Gross Weight:

5700 + 6700 / 6500 + 7500 kg

Case Dimension:

5900 x 2100 x 1400 mm + 4800 x 2100 x 1800

mm

Hydraulic Cut-off

Machine

Model:

HC-1

Blade Size:

20 x 70 x 1170 mm

Case Dimension:

packed with Roll Forming Machine

Control Cabinet

Model:

CC-1

Case Dimension:

packed with Roll Forming Machine

General Specifications

Total Net / Gross Weight:

15,500 / 17,500 kg

Shipment:

In 1 x 40 Feet + 1 x 20 Feet containers

|

|

|

Summary of the Roll Forming Line Components:

-

Uncoiler

- Single head, 4-leaved design.

- Coil expansion/collapse via a screw mechanism.

- The shaft is inserted into the coil and tightened.

- The shaft is mounted on a bush block and rotated by the pinch roll.

-

Roll Forming Machine

- Comprises 17 forming stations.

- Used to form corrugations in the sheet.

-

Hydraulic Cut-Off Machine

- Uses a hydraulic cylinder to drive the shear slowly.

- Shear consists of a fixed lower knife and a moving upper knife.

- Sheet is clamped with a spring-operated clamp during cutting.

-

Hydraulic unit includes:

- Hydraulic pump and AC motor on a steel tank base.

- Oil filter, filler cap, oil level indicator, supply/return flanges.

- Control station includes pressure gauge, valves, and piping.

-

Control Cabinet

- Contains control panel for both hydraulic and forming machines.

- Includes limit switches, emergency stop, and electric cables.

-

Functions:

- Start/stop the forming machine.

- Start/stop the hydraulic power pack.

- Control the hydraulic cylinder for the cut-off machine.

Specifications:

| Decoiler | Model: | DC-1 |

|---|---|---|

| Capacity: | 8 Tons | |

| Shaft Diameter: | 175 mm | |

| Net / Gross Weight: | 3100 / 3500 kg | |

| Case Dimension: | 2700 x 1300 x 1500 mm | |

| Roll Forming Machine | Model: | RFM-1250 |

| Corrugation Type: | Pitch 76.2 +/- 1 mm; Depth 18 +/- 1.5 mm | |

| Forming Roller Stations: | 16 Stations | |

| Forming Roller size: | 150 mm (for soft quality sheet) | |

| Forming Speed: | 12 meters / min | |

| Motor: | 10 HP | |

| Capacity Width: | 1000 to 1250 mm | |

| Capacity Length: | up to 9999 mm (optional piler table required for maximum length you wish to produce) | |

| Material of Sheet: | Soft Quality (Annealed) Galvanized Sheet | |

| Sheet Thickness: | 0.3 to 0.7 mm | |

| Net / Gross Weight: | 5700 + 6700 / 6500 + 7500 kg | |

| Case Dimension: | 5900 x 2100 x 1400 mm + 4800 x 2100 x 1800 mm | |

| Hydraulic Cut-off Machine | Model: | HC-1 |

| Blade Size: | 20 x 70 x 1170 mm | |

| Case Dimension: | packed with Roll Forming Machine | |

| Control Cabinet | Model: | CC-1 |

| Case Dimension: | packed with Roll Forming Machine | |

| General Specifications | ||

| Total Net / Gross Weight: | 15,500 / 17,500 kg | |

| Shipment: | In 1 x 40 Feet + 1 x 20 Feet containers |

VIDEO OF ROLL FORMING LINE FOR MAKING SINUSOIDAL / WAVE PROFILE CORRUGATED SHEETS

Decoiler

Decoiler

Hydraulic Decoiler

Hydraulic Decoiler

Duplex

Roll Forming Line to make both Sinusoidal and Trapezoidal Profiles

Duplex

Roll Forming Line to make both Sinusoidal and Trapezoidal Profiles