|

|

| Rotary Tablet Press (Compression) Machines | Strip Sealing Machines | Blister Packing Machines |

|

|

|

|

|

|

|

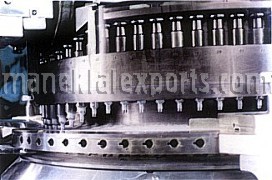

'JM' Standard |

'JM' GMP |

'JS' Standard |

'JS' GMP |

| Model: | JM-6 | JM-8 | JM-10 | JM-12 | JM-16 | JS-16 | JS-20 | JS-23 |

|---|---|---|---|---|---|---|---|---|

| Type: | Single Sided - Standard & GMP type | Single Sided - Standard & GMP type | ||||||

| No. of Stations: | 6 | 8 | 10 | 12 | 16 | 16 | 20 | 23 |

| Toolings Type: | D | D | D | D | B | D | D | B |

| Max. Compressing Pressure (Tons): | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 10 | 10 | 6.5 |

| Max. Tablet Size (mm): | 25 | 25 | 25 | 25 | 16 | 25 | 25 | 15 |

| Max. depth of fill (mm): | 20 | 20 | 20 | 20 | 16 | 20 | 20 | 16 |

| Motor (HP): | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Turret RPM (Min. / Max): | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 |

| Output (Tablets per Minute) Min. / Max.: | 108 / 200 | 145 / 265 | 180 / 330 | 220 / 400 | 300 / 530 | 290 / 450 | 360 / 560 | 460 / 760 |

| Net / Gross Weight (kgs.) GMP: | 950 / 1450 | 1200 / 1800 | ||||||

| Dimensions (m) GMP: | 0.94 x 0.94 x 1.96 | 1.30 x 1.30 x 2.34 | ||||||

| Net / Gross Weight (kgs.) Standard: | 650 / 1150 | 850 / 1450 | ||||||

| Dimensions (m) Standard: | 0.94 x 0.94 x 1.70 | 1.10 x 1.05 x 1.95 | ||||||

|

|

|

|

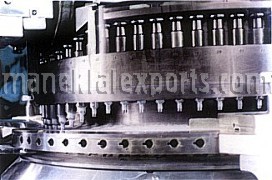

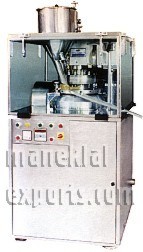

'JD' series Standard |

'JD' series GMP |

'DH' series GMP |

| Model: | JD-23 | JD-27 | JD-35 | JD-45 | DH-45 | DH-55 | DH-65 | DH-71 |

|---|---|---|---|---|---|---|---|---|

| Type: | Double Sided - Standard & GMP type | Double Sided - GMP type | ||||||

| No. of Stations: | 23 | 27 | 35 | 45 | 45 | 55 | 65 | 71 |

| Toolings Type: | D | D OR B | B | BB | D | B | BB | BB |

| Max. Compressing Pressure (Tons): | 10 | 6.5 | 6.5 | 6.5 | 10 | 6.5 | 6.5 | 6.5 |

| Max. Tablet Size (mm): | 25 | 25 / 16 | 16 | 13 | 25 | 16 | 13 | 11 |

| Max. depth of fill (mm): | 20 | 20 / 16 | 16 | 16 | 20 | 16 | 16 | 16 |

| Motor (HP): | 3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 |

| Turret RPM (Min. / Max)#: | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 20 / 50 | 20 / 50 | 20 / 50 | 20 / 50 |

| Output (Tablets per Minute) Min. / Max.: | 850 / 1520 | 980 / 1780 | 1260 / 2310 | 1620 / 2970 | 1800 / 4500 | 2200 / 5500 | 2600 / 6500 | 2850 / 7100 |

| Net / Gross Weight (kgs.) GMP: | 1500 / 2200 | 3200 / 4000 | ||||||

| Dimensions (m) GMP: | 1.35 x 1.35 x 2.35 | 1.60 x 1.60 x 2.35 | ||||||

| Net / Gross Weight (kgs.) Standard: | 1100 / 1800 | N.A. | ||||||

| Dimensions (m) Standard: | 1.20 x 1.20 x 1.95 | N.A. | ||||||

#Note: With 'JD' series GMP models the speed will be between 20 to 40 RPM

*GMP: Goods Manufacturing Process

Video of the Rotary Tablet Press Machine Model: JD-23 - GMP Type

|

|

|

Punches and Dies |

|

|

|

|

Dust Extraction Unit |

Tablet De-Duster |

|

|

| Model: | SSM-2 | SSM-4 | SSM-6 | SSM-8 | SSM-10 |

|---|---|---|---|---|---|

| Min. Output (Tablets/Minute): | 600 | 1200 | 1800 | 2400 | 3000 |

| Max. Output (Tablets/Minute): | 850 | 1700 | 2400 | 3000 | 3500 |

| Foil Width (mm): | 70 | 140 | 210 | 250 | 300 |

| Motor (HP): | 1 | 1 | 1 | 1 | 1 |

| Heater: | 2 x 500W | 2 x 500W | 2 x 1000W | 2 x 1200W | 2 x 1500W |

Video of the model SSM-6: GMP Type

Products Packed: Tablets, Dragees, Snapfit Capsules, Soft Gelatin Capsules, etc

Packing Material: Base Film: PVC Opaque or Transparent (thermoformable) and non-toxic, PVC with PVDC coating, PVC with PE/PVDC

Lidding Material: Aluminium (hard) with heat-sealable lacquer or PVDC coating

Operation:

The machine is used to Form, Fill and Seal Pharmaceutical products like tablets, capsules, dragees, etc. in blister packs. PVC base film web is drawn off from a reel and fed into the blister-forming unit where blisters are continuously formed. The web is then passed over the guide track where the product is filled into the blisters by a suitable automatic filling unit and led to the sealing unit. Aluminium foil is drawn off a separate reel and is fed to the sealing unit where it is sealed with the base web, thus sealing the product hermetically. The filled and sealed web is then fed by an indexing mechanism into a pack punch unit where the packs are separated from the web. The web trim is sheared off to allow collection. The blister pack may either be collected in bins or be conveyed over a belt for further handling. The machine could also be linked to a cartoner.

|

|

|

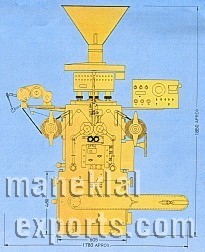

Model: 100 CH-CW |

Model: 150 CH-CW / 240 CH-CW |

| Model: | 100 ch-cw | 150 ch-cw | 240 ch-cw |

|---|---|---|---|

| PVC Base Film Width max. (mm): | 120 | 120 | 210 |

| PVC Film Thickness max. (mm): | 0.2 - 0.3 | 0.2 - 0.3 | 0.2 - 0.3 |

| PVC Reel Diameter max. (mm): | 440 | 440 | 440 |

| Aluminium Foil Width max. (mm): | 116 | 116 | 206 |

| Aluminium Foil Thickness max. (mm): | 0.02 - 0.03 | 0.02 - 0.03 | 0.02 - 0.03 |

| Aluminium Foil Roll Diameter max. (mm): | 210 | 210 | 210 |

| Total Forming Area min. (mm): | 120 x 25 | 120 x 25 | 210 x 25 |

| Total Forming Area max. (mm): | 120 x 102 | 120 x 102 | 210 x 102 |

| Pack Length (mm): | 110 | 110 | 200 |

| Pack Width (mm): | 100 | 100 | 100 |

| Forming Depth (mm): | 10 | 10 | 10 |

| Output (Packs) / (tabs/min.): | 100 / 1000 | 150 / 1500 | 240 / 2400 |

| Power Requirement (kW): | 2.5 | 4.5 | 9.0 |

| Net / Gross Weight (Kgs.): | 600 / 900 | 1050 / 1500 | 2000 / 2600 |

| Overall Dimensions (m): | 1.6 x 1.0 x 1.6 | 2.3 x 1.0 x 1.9 | 3.6 x 1.0 x 1.9 |

| Shipping Volume (m3 ): | 2.6 | 4.4 | 6.9 |