Machines for the Plastic Industry

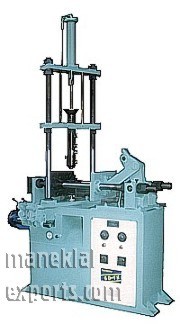

INJECTA - Horizontal Hydraulic Plastic Injection Moulding Machines

Semi Automatic Plunger Type MODEL:

Fully Automatic Plunger Type MODEL:

Fully Automatic Screw Type MODEL:

Horizontal Hydraulic, Semi and Fully Automatic Plastic Injection Moulding Machines (Plunger Type)

MODEL:

IN - 60

IN - 75

IN - 100

IN - 125

Max. Moulding Capacity* (gms.):

60

75

100

125

Max. Injection Pressure (kg / cm2) / (psi):

1000 / 15000

1000 / 15000

1000 / 15000

1000 / 15000

Max. Plasticising Capacity*

7.20

9.00

10.00

10.00

Max. Plasticising Capacity*

10.80

12.00

13.00

13.75

Max. Shots per Hour*

120

120

100

80

Max. Shots per Hour*

180

160

130

110

Max. dimensions of mould L x B x H (mm):

245 x 250 x 250

270 x 250 x 270

290 x 300 x 300

290 x 300 x 300

Max. Mould Opening (mm):

225

250

300

320

Number of Tie Bars (nos.):

2

2

4

4

Clear Gap between Tie Bars (mm):

275

300

320 x 145

320 x 145

Centre Height of Injection Nozzle (mm):

175

190

225

225

Clamping Force (tons):

30

35

60

80

Max. Pump Pressure (adjustable) (kg / cm2):

140

140

140

140

Oil Tank Capacity (liters):

100

115

150

150

Electric Motor (HP):

7.5

10

12.5

12.5

Total Heating Load (kW):

1.5

1.75

3.0

4.0

Approximate Machine Dimensions (mm):

2300 x 600 x 1400

2500 x 600 x 1400

2800 x 750 x 1600

3000 x 750 x 1600

Approximate Net / Gross Weight (Kgs.):

1000 / 1300

1300 / 1500

2500 / 2800

2600 / 3000

Approximate Shipping Volume (m3):

2.85

3.10

4.70

5.00

Horizontal Hydraulic, Fully Automatic Plastic Injection

Moulding Machines (Screw Type)

MODEL:

IN - 60S

IN - 75S

IN - 100S

IN - 125S

Screw Diameter (mm):

30

30

35

35

Max. Moulding Capacity* (gms.):

60

75

100

125

Max. Injection Pressure (kg / cm2):

1100

1200

1800

1800

Max. Plasticising Capacity* (kg / hr):

14.4

18

18

22.5

Max. Shots per Hour* (nos / hr):

240

240

180

180

Dry Cycles per Hour:

400

400

350

350

Max. Swept Volume (cm3):

77

90

120

140

Max. dimensions of mould L x B x H (mm):

245 x 250 x 250

270 x 250 x 270

290 x 300 x 300

290 x 300 x 300

Max. Mould Opening (mm):

225

250

300

320

Number of Tie Bars (nos.):

2

2

4

4

Clear Gap between Tie Bars (mm):

275

300

320 x 145

320 x 145

Centre Height of Injection Nozzle (mm):

175

190

225

225

Clamping Force (tons):

30

35

60

80

Max. Pump Pressure (adjustable) (kg / cm2):

140

140

140

140

Oil Tank Capacity (liters):

100

115

175

200

Electric Motor (HP):

7.5

10

12.5

12.5

Total Heating Load (kW):

1.5

1.75

2.5

3.2

Approximate Machine Dimensions (mm):

2300 x 600 x 1400

2500 x 600 x 1400

2800 x 750 x 1600

3000 x 750 x 1600

Approximate Net / Gross Weight (Kgs.):

1200 / 1500

1500 / 1700

2700 / 3000

2800 / 3200

Approximate Shipping Volume (m3):

2.85

3.10

4.70

5.00

* - Depends on material, processing conditions,

individual articles, mould design, etc.

Thermoplastics Moulded:

Polystyrenes,

Polyethylenes, Polypropylenes, acrylics, ABS, flexible PVC, rigid PVC (in Screw Type

machines only), etc. Extra optional Nozzles available for moulding Nylon, Polyester,

etc.

Vertical Hydraulic, Semi-Automatic Plastic Injection Moulding Machine,

Plunger Type

Model:

40HM

Max. Moulding Capacity (gms.):

40

Stroke of Injection Plunger

(mm):

150

Injection Pressure - adjustable

(kg / cm2):

1200

Clamping Force - adjustable

(tons):

up to 4

Clamping Stroke (mm):

125

Working Base Width (mm):

175

Distance - back to barrel nozzle

(mm):

80

Distance - barrel nozzle to base

- adjustable (mm):

80 - 175

Max. Moulding Area (mm2)

5000

Electric Motor (HP):

2

Electric Heater (kW):

0.75

Approximate Machine Dimensions (mm):

1500 x 610 x 1500

Approximate Net / Gross Weight (Kgs.):

175 / 250

Approximate Shipping Volume (m3):

1.40

Model: 40-HM

Vertical Plastic Injection Moulding Machines

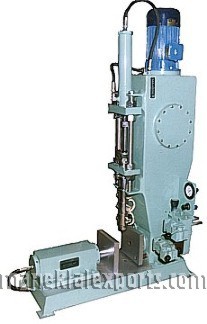

Vertical Plastic Injection Moulding Machines with Horizontal Hydraulic Toggle Locking

Features

Horizontal Toggle Locking (Hydraulic Toggle)

Injection Unit can be raised and lowered vertically as per requirement of moulds

Mould Runner center can be aligned horizontally by shifting the fixed platen

Plunger Type Machine Model 60-VH available in both Semi and Fully Automatic Type.

Screw Type Machine Model 60-VH/S available in Fully Automatic Type (Suck back provided)

MODEL: 60-VH/S

MODEL: 60-VH Fully Automatic

MODEL:

60-VH

60-VH/S

Type:

Plunger Type

Screw Type

Max. Moulding Capacity* (gms.):

60

60

Screw Diameter (mm):

--

30

Max. Swept Volume (cm3):

--

70

Max. Injection Pressure* (kg / cm2):

900

1100

Max. Plasticising Capacity*

7.2 / 10.8

-- / 14.4

Max. Shots per Hour*

120 / 180

-- / 240

Max. dimensions of mould L x B x H (mm):

200 x 200 x 200

200 x 200 x 200

Max. Mould Opening (mm):

200

200

Number of Tie Bars:

2

2

Clear Gap between Tie Bars (mm):

230

230

Injection Nozzle Centre (mould back to Runner) (mm):

30 - 80 Adjustable

30 - 80 Adjustable

Clamping Force (Adjustable) (Tons):

25 Hydraulic Toggle

25 Hydraulic Toggle

Max. Pump Pressure (adjustable) (kg / cm2):

140

140

Oil Tank Capacity (Liters):

75

75

Electric Motor (HP):

3

3 (Hydraulic System) + 2 (Screw Drive)

Total Heating Load (kW):

1.5

1.5

Approximate Machine Dimensions L x B x H (mm):

1480 x 700 x 2400

1480 x 700 x 2400

Approximate Net / Gross Weight (Kgs.):

700 / 1000

850 / 1150

Approximate Shipping Volume (m3):

3.20

3.20

Vertical Semi Automatic Bench Mounting Plastic Injection Moulding Machines (Plunger Type)

Features

Fully Hydraulic Injection and Clamping Unit

Operation by manually actuated Hydraulic Valves

Injection Unit vertically adjustable to accommodate various moulds

Fixed mould plates adjustable to align nozzle centre to mould runner

Direct mould clamping unit. Does not need adjustment for stroke as it is Direct Locking Type

Hand Moulds can be used. Automatic moulds with vertical injection can also be used

MODEL: 60-VH Semi Automatic

MODEL: AU-30-HD

MODEL:

AU-30-HD

AU-60-HD

Max. Moulding Capacity* (gms.):

30

60

Max. Injection Pressure* (kg / cm2):

800

800

Max. dimensions of mould L x B x H (mm):

150 x 150 x 100

150 x 150 x 100

Adjustment of Fixed Mould Plate (min. / max.)

(mm):

60 / 90

60 / 90

Vertical adjustment of Injection Unit to

accommodate

90 / 150

90 / 150

Maximum moulding projected area* (cm2):

30

40

Clamping Force (Tons):

7.5

7.5

Clamping Stroke (mm):

75

75

Electric Motor (HP):

2

2

Approximate Machine Dimensions L x B x H (mm):

1100 x 680 x 1250

1100 x 680 x 1325

Approximate Net / Gross Weight (Kgs.):

300 / 450

350 / 500

Approximate Shipping Volume (m3):

1.30

1.35

* - Depends on material, processing conditions,

individual articles, mould design, etc.

Thermoplastics Moulded:

Polystyrenes,

Polyethylenes, Polypropylenes (Extra optional Nozzles available for moulding Nylon,

Polyester, acrylics, soft PVC, etc.)

PLASJET - Horizontal Fully Automatic Plastic Injection Moulding Machines with Direct Drive Screw

Soft mould closing and opening with speed control. Low Pressure mould protection provided

Direct Hydraulic Screw drive with reciprocating injection carriage.

Multi-Stage Injection pressure / speed

Suck-back screw for melt decompression

Injection with screw rotation facility

Hydraulically and electrically interlocked safety gate

Central lubrication

PJ-65 and PJ-80 with Toggle Type mould clamping unit

PJ-100 and PJ-180 with Direct Hydraulic Telescopic Ram type Clamping Unit

MODEL:

PJ - 65

PJ - 80

PJ - 100

PJ - 180

Screw Diameter (mm):

35

35

40

55

Injection Pressure (Bar):

1760

1760

1350

1500

Stroke Volume (cm3):

105

120

201

380

Screw Stroke (mm):

110

135

160

190

Max. Injected Weight (Gms.):

95

117

180

340

Injection Rate (Gms./Sec.):

70

82

138

159

Plastisizing Rate (Gms./Sec.):

8.7

10.5

15

22

Screw Length (max.) (L/D):

22

22

20

16

Screw Speed (RPM):

250

250

250

200

Heating Capacity (kW):

6.0

6.5

10.0

11.0

No. of Heating Zones:

4

4

4

5

Nozzle Holding Force (kN):

20

20

40

50

Clamping Unit:

Hydraulic Toggle

Hydraulic Toggle

Direct Hydraulic

Direct Hydraulic

Clamping Force (kN):

650

800

1000

1800

Mould Opening Stroke (mm):

300

300

500

550

Mould Height (min. / max.) (mm):

150 / 300

175 / 350

200

350

Max. Daylight (mm):

600

650

700

900

Clear Gap between Tie Bars (mm):

320 x 145

320 x 145

325 x 325

425 x 425

Size of Mould Plates (H x V) (mm):

500 x 325

500 x 325

525 x 525

650 x 650

Ejector Force (kN)

Mechanical

Mechanical

40

70

Ejector Stroke (mm):

90

90

95

125

Pump Drive (kW):

9.37

10.25

15

22.5

Total Connected Power (kW):

15.37

17.75

25

33.5

Oil Tank Capacity (liters):

225

250

375

500

Approximate Shipping Dimensions (mm):

3800x1000x1700

4000x1000x1700

5200x1200x1700

5600x1300x1800

Approximate Net / Gross Weight (Kgs.):

2300 / 2800

2500 / 3000

5000 / 6000

6500 / 7800

Approximate Shipping Volume (m3):

6.5

6.8

10.6

13.1

Optional Accessories:

Microprocessor Control with Mould Program Memory, Hydraulic

Ejector

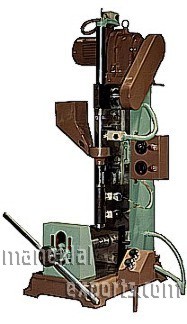

AUTOMIC - Mechanical Type Semi-automatic Vertical Plastic Injection Moulding Machines

Bench mounting type

Moulds of hand opetared machines can be used

Simple electrical system

Versatile machine suitable for moulding various textile parts, automobile parts,

industrial items, insert mouldings, electrical fittings, pens and stationary items,

jewelry boxes, gift articles, hardware items, plumbing items, caps, closures, house hold

articles, etc.

Model:

AM-15

AM-30

AM-60

AM-100

AM-125

AM-180

Max. Moulding Capacity (gms.):

15

30

60

100

125

180

Max. Plasticising Capacity (kg / hr):

1.5

2.5

3.5

4.5

5.0

7.0

Max. Shots per Hour (nos / hr):

120

120

100

80

80

80

Distance - Back to Cylinder Nose (mm):

72

75

80

90

90

120

Distance - Cylinder Nose to Base (mm):

135

165

200

225

225

250

Working Base Width (mm):

300

300

325

325

375

400

Adjustment of Clamping Vice (mm):

70

80

110

125

125

135

Hopper Capacity (gms):

500

750

800

1000

1225

2000

Electric Motor (HP):

0.25

0.5

0.5

1.0

1.0

2.0

Heating Load (kW):

1.2

1.5

1.5

2.5

2.5

3.0

Net / Gross Weight (kgs):

175 / 235

250 / 340

300 / 400

325 / 440

350 / 470

450 / 600

Overall dimensions (m):

1.0 x 0.5 x 1.0

1.2 x 0.5 x 1.05

1.35 x 0.6 x 1.2

1.6 x 0.6 x 1.3

1.8 x 0.6 x 1.3

2.0 x 0.7 x 1.5

Shipping Volume (m3):

0.50

0.65

1.00

1.25

1.45

2.10

Thermoplastics Moulded:

Polystyrenes, Polyethylenes, Polypropylenes (Extra optional Cylinders available for moulding Nylon,

Polyester, acrylics, soft PVC, etc.)