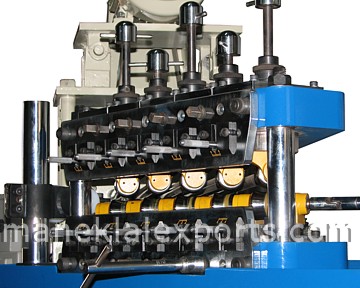

Pipe / Tube Straightening Machines

Model: SE-33 with 6 Rolls

Features:

- Machines comprise of six / ten work rolls arranged in pairs

- Rolls quickly and easily adjustable angularly to give perfect contact between the tube and the roll, over the maximum effective roll profile

- Simple setting of the machine for different sizes of tubes

- All rolls driven by two identical electric motors

- Machines fitted with indicators for vertical and angular setting of rolls

- Machines available in Single Speed and Variable Speed Options

To obtain best results from the machine, correctly designed inlet and outlet through are essential because the tube rotates at high speed and must be controlled before and after straightening.

- ROLLS: Made from alloy steel, hardened, hyperbolic profile ground and lapped. Hyperbolic profiles are designed to accept a wide range of tube diameters.

- ROLL CARRIERS: Designed to provide maximum roll stability even when fully extended.

- MAIN DRIVE: Drive to the rolls by two totally enclosed gearboxes, each with three/five output shafts, connected by universal joints. Bottom rolls and upper rolls driven independently. Gears are single helical, made from alloy steel, hardened and ground. Motors connected to the input shaft of the gearboxes by flexible coupling or ‘V’ belts.

- ENTRY GUIDES: Entry guides made from special elastomer provided for the entire range.

- GUARDS: Perspex transparent screen guard provided in front of the rolls.

- CONTROL PANEL: A control panel housing all electrical controls for running the machine is provided.

|

|

| Model: SE-15 with 10 Rolls and Optional: Counters for Up & Down Adjustment | |

|---|---|

Specifications:

| Model | SE-10 | SE-15 | SE-20 | SE-25 | SE-31 | SE-32 | SE-33 | SE-36 | SE-40 |

|---|---|---|---|---|---|---|---|---|---|

| Normal Capacity Range (Tube OD) (mm): | 1.5 - 8 | 3 - 13 | 4.5 - 16 | 6 - 25 | 8 - 40 | 13 - 65 | 20 - 100 | 25 - 125 | 30 - 150 |

| Max. Wall Thickness (mm): | 1.5 | 2.5 | 2.5 | 3.2 | 4.5 | 6 | 8 | 8.5 | 9.5 |

| Number of Rolls: | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 | 6 or 10 |

| Straightness Achievable on 6 roll machine: | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better | 1:1000 or better |

| Straightness Achievable on 10 roll machine: | 1:3000 | 1:3000 | 1:3000 | 1:3000 | 1:3000 | 1:3000 | 1:3000 | 1:3000 | 1:3000 |

| Max. Diameter Admitted (mm): | 8 | 13 | 20 | 32 | 45 | 75 | 115 | 140 | 165 |

| Max. Wall Thickness at Max. Diameter (mm): | 1.5 | 2.5 | 2 | 2.5 | 3.5 | 4.5 | 6.5 | 6.5 | 7 |

| Operating Speed on Single Speed M/c (m/min): | 18 | 36 | 36 | 30 | 30 | 30 | 30 | 30 | 30 |

| Operating Speed on Variable Speed M/c (m/min): | 0 - 18 | 0 - 36 | 0 - 36 | 0 - 30 | 0 - 30 | 0 - 30 | 0 - 30 | 0 - 30 | 0 - 30 |

Note: Capacities listed above are based on material having a yield strength not exceeding 32 kg/mm2 and are for general guidance only.

Machine with capacity in excess of those specified above available on request

|

|

| Model: SE-36 with 6 Rolls | Model: SE-40 with 6 Rolls |

|---|---|

|

|

| Model: SE-10 with 10 Rolls | |

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-15 with Optional Counters for Up & Down Adjustment

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-40

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-36

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-33

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-35

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-15

VIDEO OF TUBE STRAIGHTENING

MACHINE: SE-10

Entry Guides supplied with the Tube

Straightening machines

Entry Guides supplied with the Tube

Straightening machines

|

|

|

|

|

| Model: SE-15 with 10 Rolls | Model: SE-20 with 6 Rolls | Model: SE-31 with 6 Rolls |

|---|

Spare set of rolls for the straightening machine

We can supply Hyperbolic Profile Straightening Rolls for any make / brand of Tube Straightening Machines