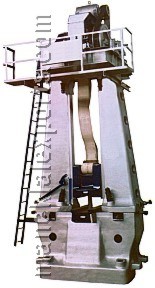

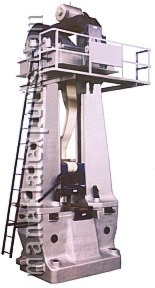

Friction Drop Hammers

|

|

-

Suitable for precision forging for:

- Automobile

- Railways

- Defense

- Aeronautics

- Hand Tools

- Agricultural

- Bicycle

- Other engineering industries

Anvil Block:

- Made of grey cast iron weighing approximately 20 times the nominal capacity of the hammer

- Machined on both top and bottom faces to hold die holder firmly and maintain position of columns

- Die holder is forged from high grade alloy steel, hardened, and positioned with alloy steel tapered wedge

Columns, Slides, and Tup:

- Cast steel columns, annealed and machined

- Positioned by a large spigot on each foot fitting into a machined recess in the anvil block

- Columns locked with tapered wedges of alloy steel for firm alignment

- Ensures accurate grinding of tup (made of EN-9 cast steel)

- Clearance between tup and guideways maintained with tapered wedge (brings columns inward) and drawback bolt (pushes columns outward)

- Synthetic rubber mat on anvil block dampens shock vibrations, increases life of tup and columns, and ensures smooth long-term operation

Gear Head:

- Heavy duty gear head fabricated from rolled steel sections, mounted on top of columns

- Drive via 'V' belts from high torque AC electric motor, through flywheel and reduction gears to lifter shaft

- Friction lifting system on lifter shaft uses double ball bearings and a central phosphorous bronze bearing

- Friction lifter: constantly rotating drum and brake-lined steel band

- Band anchored at one end to lifter drum, other end carried by camshaft actuated by a lever

- Lever operated by pulling cord, passing through capstan bush attached to lifter shaft

- Puling the cord tightens brake around drum via camshaft; lifter drum rotates and tup is lifted with nylon belt

- Releasing the cord disengages friction band, allowing free fall of tup (spring-loaded arrangement)

- Spring-loaded buffer acts as stopper for lifting drum in rest position

- Positive water cooling for friction drum to prevent excessive heating

Specifications:

| Model: | FDH-300 | FDH-500 | FDH-750 | FDH-1000 | FDH-1250 | FDH-1500 | FDH-2000 | FDH-2500 | FDH-3000 |

|---|---|---|---|---|---|---|---|---|---|

| Size of Hammer (kg) | 300 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 |

| Weight of Tup (kg) | 300 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 |

| Space between slides (mm) | 360 | 432 | 495 | 542 | 575 | 620 | 670 | 727 | 800 |

| Stroke Maximum (mm) | 1450 | 1565 | 1630 | 1700 | 1700 | 1835 | 1835 | 1980 | 2100 |

| Max weight top die (kg): | 100 | 155 | 225 | 280 | 330 | 460 | 510 | 650 | 740 |

| Tup Front to Back (mm): | 330 | 400 | 430 | 490 | 520 | 550 | 610 | 660 | 700 |

| Total height of machine (mm) | 5000 | 5500 | 5590 | 6020 | 6300 | 6600 | 6750 | 7000 | 7250 |

| Max. number of blows per minute: | 45 - 95 | 44 - 90 | 40 - 82 | 36 - 75 | 36 - 75 | 32 - 66 | 32 - 66 | 30 - 62 | 25 - 56 |

| Max. weight of Job (kg): | 0.5 | 1 | 2 | 3 | 5 | 10 | 20 | 35 | 50 |

| Motor (HP): | 20 | 30 | 40 | 50 | 60 | 70 | 100 | 125 | 150 |

| Approximate Weight (kg): | 13000 | 21000 | 27000 | 34000 | 42000 | 50000 | 63000 | 71000 | 84000 |

Standard Accessories: Electric motor and starter

|

|

|