Leaf Spring Making Machines

Hot Leaf Taper Rolling Machine

Features:

- Two rollers of EN-8 Forged Steel fitted in Gun Metal Bushes with lubrication system

- Bottom Roll with 4 steps for bending by eccentric taper roll drive

- Eccentric drive shaft arrangement for the bottom roll through an eccentric cam — this squeezes the spring edges

Main gears made of EN-8 Forged Steel, machine cut and perfectly matched to give smooth running. Provision given on the side for squeezing edges of flats.

Specifications:

| Model: | LSTR-10/12 |

|---|---|

| Bottom Roll Diameter: | 10” with 4 steps |

| Top Roll Diameter: | 12” |

| Electric Motor: | 5 HP |

| Net / Gross Weight: | 1200 / 1400 kg. |

| Dimensions: | 2.0 x 2.0 x 1.9 m |

| Shipping Volume: | 8.0 m3 |

Standard Accessories: Electric Motor, Starter

Double Ended Eye Grinding Machine

Features:

- Two Cup wheel arrangement with central lever force arrangement to clamp eye centre position

- Both ends ground simultaneously

Specifications:

| Model: | LSEG-125/80 |

|---|---|

| Eye Grinding Capacity: | 125 x 80 mm |

| Grinding Wheel Size: | 12" x 4" |

| Electric Motors: | 5 HP x 2 nos. |

| Net / Gross Weight: | 1000 / 1200 kg. |

| Dimensions: | 2.0 x 1.7 x 1.7 m |

| Shipping Volume: | 6.0 m3 |

Standard Accessories: Electric Motor, Starter, Grinding Wheels

VIDEO OF 'MANEK' DOUBLE ENDED EYE GRINDING MACHINE MODEL: LSEG-125/80

Heavy duty Shearing Machine

Features and Specifications:

- Machine made of M.S. sections and flats. An all steel body, nut bolted and welded structure

- Used for cutting EN-45 steel spring flats

- Equipped with alloy hardened cutting blades

- Shaft and pinion are of forged steel. Gears of Cast Iron (hobbing machine cut)

- Speed: 38 strokes a minute

- Operation by clutch system, operated by a foot lever

- Drive through a 5 HP electric motor with necessary pulley and 'V' belts

- Capacity to cut maximum 200 mm wide x 20 mm thick EN-45 flats

Cambering Press

Features:

- All fabricated design

- Supplied with hydraulic power pack with 3 HP motor complete with 15 Tons hydraulic cylinder double acting, hydraulic pump, foot switch, limit switch, etc.

- Capacity maximum chambering length x width: 1800 x 100 mm

- Supplied with one set of die and punch for hot leaves chambering Operation:

- The downward Movement of the press is operated by a foot switch. On releasing the foot switch, the press goes upwards and stops at the position of the limit switch. By adjusting the position of the limit switch, we can control the stroke of the hydraulic cylinder.

- The position of the bottom die can be lowered by fitting it in the additional holes provided on the side beams.

Eye Rolling Machine

Features:

- All fabricated design

- Supplied with quick lifting centre pin arrangement with hand operated lever

- Capacity maximum of leaf eye rolling 100 x 12 mm Installation:

- The machine should be installed on a concrete foundation close to the heating furnace. Hot end chambers / pre-bending of leaf spring should be done.

- After Hot end chamfering of lead on press, hot flat end should be reheated. Two Eye Rolling diameter pins should kept ready. One pin is used for eye rolling while the other pin cools in the water tank kept below the eye rolling machine. Corresponding to the pin size, the required bush is to be mounted on the Eye Rolling Machine. Please make all size pins and corresponding bushes as per your requirement.

Heating & Tempering Furnace

Heating Furnace

- Furnace for heating leaves, having a maximum temperature of 1000°C

- Fire brick lining arrangement

- Furnace door: 3' Wide x 2' High x 6.5' Deep

- Double heated with oil-fired burner

- 5 HP Blower

- Pyrometer (0 to 1000°C)

Tempering Furnace

- Tempering Furnace, having a maximum temperature of 400 to 600°C

- Furnace door: 3' Wide x 4' High x 6.5' Deep

- Pyrometer (0 to 700°C)

End Heating and Centre Heating Furnace

- Furnace for heating the ends of the leaf spring flats for making taper cut and for heating the centre of the leaf spring flats for making a dimple in the centre.

- Furnace fitted with burner and blower.

- Furnace door: 3' Wide x 6' High, opening on both sides

Automatic Quenching Tank with Conveyor Belt

Quinching Tank

Quinching Tank

Features and Specifications:

- After hot cambering on the cambering press, the hot leaves are pushed into quenching oil tank and are cooled down on conveyors to room temperature. These leaves are then cooled in open air to give required hardness to the leaves

- With Oil Cooling Tower arrangement

- Electric Motors: 1 HP motor for circulating quenching oil and 3 HP motor for movement of conveyor through reduction gearbox

- Supplied with quenching oil storage tank of capacity 8000 to 10000 liters

- Quenching oil is used for hardening of the leaf spring

Oil Cooler

Oil Cooler

- The machine comes with a reduction 4 HUD gearbox, 3 HP / 1440 RPM Motor. There are 4 sprocket wheels, which guide the chain and slats.

- The quenching oil tank is fitted with an electronic temperature gauge. It is also fitted with an alarm which will sound if the temperature crosses 80o C or as preset on the thermocouple.

- The flash point of the quenching oil is 130o C. To avoid fire, it is essential that the temperature is maintained below 100o C.

- The optimum temperature for getting good results for hardening is 60o C to 70o C.

Oil Pre-Heating Pumping Unit

Working:

- This unit has a 3.5 kW / 3 Phase heater and 2 nos. 1 HP duplex motors - oil from storage tank goes to the heater of pumping unit and is heated up to 100 degrees centigrade

- Once the temperature is achieved, the oil is circulated through the pump unit

- Complete oil pumping requirement of both the furnaces is done by this one unit

- If there is a brake-down on one motor due to any reason, another pumping unit fitted at the same base is started to avoid production loss

Power Presses

Features:

- Pillar type all steel body press for cutting - pressing - embossing

- Capacity 50, 80 and 100 Tons

- Supplied with a suitable electric motor

- Supplied with suitable die and punch set for Champer Cutting / Cover Cutting / Dimple Forming / Chambering / Straightening / etc.

Spring Scraging and Camber Testing Machine

- Supplied with Hydraulic Power Pack with 2 HP motor

- Hydraulic cylinder double acting 10 ton capacity, 200 mm stroke

- 2 nos. track mounted trolley with 'V' notch with eye pin for length range 400 to 1800 mm

- All types of assembly springs can be scraged, chambered and corrected

- Buckling reverse test can also be done on the machine

- A vertical and horizontal scale indicator provided to reading chamber deflection

Brinell Hardness Testing Machine

- Brinell Hardness Tester is a production type machine designed for measuring the Brinell Hardness of steels and other metals that are flat, round or irregular in shape. The machine is sensitive, accurate and easy to operate.

- The machine consists of a ‘J’ frame, main lever, hanger, elevating screw, loading - unloading mechanism and damper system. The load is applied on the job through a ball indentor. It is applied through a lever mechanism.

- The main lever carries three male vees one for hanger second for spindle shaft and third for pivot vee. The elevating screw can be moved up and down by rotating hand wheel. There are six detachable weight out of which four are each equivalent to 500 kgf and two are each equivalent to 250 kgf to be made use of for application of desired load in addition to the bottom weight equivalent to 500 kgf. The operating lever is provided for loading & unloading.

- The damper system consists of main cylinder, piston, valve disc, connecting rod and metering valve. The damping sensitivity is adjusted by the metering valve. The connecting rod and piston is actuated through cam, mounted on cam shaft while operating.

Specifications:

- Load range: 500, 750, 1000, 1500, 2000, 2500 & 3000 kgf

- Maximum test height: 254 mm

- Depth of throat: 150 mm

- Gross weight: 220 kg (Approx.)

- Height: 860 mm (Approx.)

- Size of base: 495 × 255 mm (Approx.)

Endurance Testing Machine

The main purpose of Endurance Testing Machine is to test Leaf spring Assemblies for giving

continuous jerks for the specified number of cycle for e.g. One Hundred Thousand strokes

or more. This test gives us feedback on the life of leaf spring material, spring properties like

camber and reduction in load bearing properties.

We can also plot graph of load v/s deflection of the assembly by taking note of the load cell

reading in kilos & the deflection reading in mm on the scale provided.

Technical Specifications:

- Power Pack: Solenoid operated D. C. V., 12.5 HP motor, Hydraulic pump, Pressure gauge , Hose pipes, Water cooler

- Hydraulic Cylinder - Press Body: M.S. fabricated to withstand 15 Ton max load exerted by cylinder

- Load cell & indicator

- Stroke Counter: Proximity switch & display stroke counter

- Cycle on: Two proximity switches to control stroke length

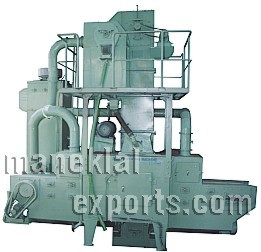

Shot Peening Machine

Brief Description of the working of the machine:

- Shot Peening machine is used for surface peening of leaf springs to give extra life to the spring.

- The leaf spring is placed on the conveyor belt, which moves at a speed of 3 meters/minute.

- In the main blasting chamber concave surface of the spring is bombarded with very high velocity shots.

- The impact of the shots leaves a impinge impression on the surface which increases the fatigue life of the spring by 50%

| Main parts of the machine: |

|---|

| Main chamber/ Blasting chamber: Here the spring is subjected to shot peening. The inner side is protected by liners made of rubber and M.S. Care has to be taken to see that the condition of the liner is inspected every week and necessary replacement be done wherever wear & tear is observed. |

| Shot Peening Wheel: Here the shots are thrown at very high velocity by the wheel and blades. Main parts for inspection are: Cage, Impeller, Blades, bare wheel, bearing assembly, V belts. The blades should be balanced to avoid vibrations and breakage. |

| Pneumatic Cylinder: This operates on compressed air, which is supplied through a solenoid valve. The main function is to start supply of the shots and stop supply when shutting off the machine. |

| Separator: This has a screen to separate the big unwanted particle, which may have accidentally entered the shots. |

| Bucket elevator: This conveys the shots from the bottom of the machine to the separator at the top. The bucket belt can be tightened by the screws at the top. The belt and the buckets have to be inspected every 15 days for wear. |

| Screw conveyor: This conveys the shots to the bucket elevator. |

| Main conveyor system: This conveys the leaf springs through the machine. There is a variable speed drive unit for controlling the speed of the belt. |

| Doors: They are provided for inspection of the liners in the main chamber. These are fitted with limit switches, which provide safety that the machine will not operate when the doors are open. |

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS