Bucket

/ Paint Can Handle Making Machine

Model: BHM-25EP - For Handle Type East-West (Bent Ends) with Plastic Grip

Specifications:

Model:

BHM-10EW

BHM-25EW

BHM-10EP

BHM-25EP

Type of Handle:

East-West

(Bent Ends) without Plastic Grip

East-West

(Bent Ends) without Plastic Grip

East-West

(Bent Ends) with loose Plastic Grip

East-West

(Bent Ends) with loose Plastic Grip

Wire Size (mm):

3 - 4

3 - 5

3 - 4

3 - 5

Suitable to make

handle of bucket capacity:

5 -

10 liters

15 -

25 liters

5 -

10 liters

15 -

25 liters

Production Capacity

(handles / minute):

30

30

30

30

Motor:

3 HP

3 HP

3 HP

3 HP

Net / Gross Weight

(kg):

1500 /

2300

1800 /

2600

1500 /

2300

1800 /

2600

Dimensions (m):

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

Shipping Volume (m3

):

9.0

9.0

9.0

9.0

Model: BHM-10EP - For Handle Type East-West (Bent Ends) with Plastic Grip

VIDEO

VIDEO of EAST-WEST (BENT ENDS) Type Bucket Handle

Making Machines

Standard Accessories:

Electric Motor

Control Panel

Coil Stand

One set of toolings (for any one size of handle)

Extra Accessories:

Additional dies for other sizes of bucket handles (must be ordered along with the machine)

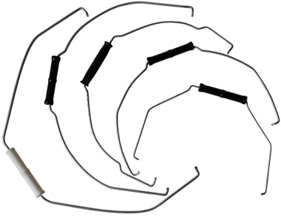

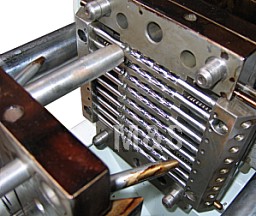

Additional Die for East-West (Bent Ends) Type Bucket Handle

Model: BHM-25HK - For Handle Type OK (Hook Ends) with Plastic Grip

Specifications:

Model:

BHM-10HW

BHM-25HW

BHM-10HK

BHM-25HK

Type of Handle:

OK

(Hook Type) without Plastic Grip

OK

(Hook Type) without Plastic Grip

OK

(Hook Type) with loose Plastic Grip

OK

(Hook Type) with loose Plastic Grip

Wire Size (mm):

3 - 4

3 - 5

3 - 4

3 - 5

Suitable to make

handle of bucket capacity:

5 -

10 liters

15 -

25 liters

5 -

10 liters

15 -

25 liters

Production Capacity

(handles / minute):

30

30

30

30

Motor:

3 HP

3 HP

3 HP

3 HP

Net / Gross Weight

(kg):

1500 /

2300

1800 /

2600

1500 /

2300

1800 /

2600

Dimensions (m):

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

Shipping Volume (m3

):

9.0

9.0

9.0

9.0

VIDEO

VIDEO of OK (HOOK ENDS) Type Bucket Handle

Making Machines

Additional Die for OK (Hook Ends) Type Bucket Handle

Additional Die for OK (Hook Ends) Type Bucket Handle

Additional Die for OK (Hook Ends) Type Bucket Handle

Standard Accessories:

Electric Motor

Control Panel

Coil Stand

One Set of Toolings (for any one size of handle)

Extra Accessories:

Additional dies for other sizes of bucket handles (have to be ordered along with the machine)

Model: BHM-10R - For Handle Type Regular (Notches at Ends)

Specifications:

Model:

BHM-10R

BHM-25R

Type of Handle:

Regular

(Notches at Ends)

Regular

(Notches at Ends)

Wire Size (mm):

3 - 4

3 - 5

Suitable to make

handle of bucket capacity:

5 -

10 liters

15 -

25 liters

Production Capacity

(handles / minute):

30

30

Motor:

3 HP

3 HP

Net / Gross Weight

(kg):

1500 /

2300

1800 /

2600

Dimensions (m):

3.2 x

1.35 x 2.05

3.2 x

1.35 x 2.05

Shipping Volume (m3

):

9.0

9.0

VIDEO

VIDEO of REGULAR (NOTCHES AT ENDS) Type Bucket Handle

Making Machines

Standard Accessories:

Electric Motor

Control Panel

Coil Stand

One Set of Toolings (for any one size of handle)

Extra Accessories:

Additional dies for other sizes of bucket handles (have to be ordered along with the machine)

Model: IN-75S

Specifications:

Model:

IN - 75S

IN -

100S

Screw Diameter (mm):

30

35

Max. Moulding Capacity* (gm.):

75

100

Max. Injection Pressure (kg/cm2

):

1200

1800

Max. Plasticising Capacity* (kg/hr):

18

18

Max. Shots per Hour* (no/hr):

240

180

Dry Cycles per Hour:

400

350

Max. Swept Volume (cm3

):

90

120

Max. dimensions of mould L x B x H (mm):

270 x 250 x 270

290 x 300 x 300

Max. Mould Opening (mm):

250

300

Number of Tie Bars (nos.):

2

4

Clear Gap between Tie Bars (mm):

300

320 x 145

Centre Height of Injection Nozzle (mm):

190

225

Clamping Force (tons):

35

60

Max. Pump Pressure (adjustable) (kg/cm2

):

140

140

Oil Tank Capacity (liters):

115

175

Electric Motor (HP):

10

12.5

Total Heating Load (kW):

1.75

2.5

Approximate Machine Dimensions (mm):

2500 x 600 x 1400

2800 x 750 x 1600

Approximate Net / Gross Weight (Kg.):

1500 / 1700

2700 / 3000

Approximate Shipping Volume (m3

):

3.10

4.70

Model: IN-100S

Thermoplastics Moulded:

Polystyrenes

Polyethylenes

Polypropylenes

Acrylics

ABS

Flexible PVC

Rigid PVC (in Screw Type machines only)

Extra Optional Nozzles:

Available for moulding Nylon

Available for moulding Polyester

Depends on material, processing conditions,

individual articles, mould design, etc.

VIDEO

VIDEO OF IN-75S INJECTION MOULDING MACHINE

VIDEO

VIDEO OF IN-100 INJECTION MOULDING MACHINE

VIDEO

VIDEO OF 10 CAVITY INJECTION MOULDING DIE FOR MAKING PLASTIC GRIPS

9 Cavity Die for making Plastic Grips with IN-75S

10 Cavity Die for making Plastic Grips

16 Cavity Die for making Plastic Grips with IN-100S

Plastic Injection Moulding Machine with 2 Station - 16 Cavity Die for

moulding Fixed Plastic Grips on Bucket / Paint Can Handles

Model: MIM-80

Features:

Hydraulics of Sufon / Hyten

Two side Hydraulic Ejector

4 Zone Ceramic Heater

Oil Cooler provided

Carriage Unit UP / DOWN hydraulic system

PLC of Streamline

Linear Scale of Opkon / Orbital

PLC Control Panel

Specifications:

Model:

MIM-80

Max. Moulding Capacity:

80 gm

Screw Barrel Diameter:

30 mm

Tie Bar Distance:

380 x 280 mm

Tie Bar Thickness:

50 mm

Die Mould Size:

200 to 300 mm

Die Hold Size:

4.25” x 4.25” /

6.75” x 6.75”

Machine Opening:

200 mm

Electric Motor:

7.5 HP

Electric Heater:

0.80 kW

Approximate Net / Gross Weight:

1800 / 2200 kg

Approximate Machine Dimensions:

2.1 x 1.7 x 1.7 m

Approximate Shipping Volume:

6.50 m3

Standard Accessories:

Electric Motor

Control Panel

PLC Unit

Hydraulic Power Pack

Tool Kit

Optional Accessories:

Die for moulding plastic grips on bucket handles

VIDEO

VIDEO OF MIM-80 INJECTION

MOULDING MACHINE

16 Cavity Die for moulding Plastic Grips

Vertical Hydraulic, Semi-Automatic Plastic Injection Moulding Machine,

Plunger Type

Model: 40HM

Die for fixing Plastic Grips

Model:

40HM

Max. Moulding Capacity (gm.):

40

Stroke of Injection Plunger

(mm):

150

Injection Pressure - adjustable

(kg/cm2

):

1200

Clamping Force - adjustable

(tons):

up to 4

Clamping Stroke (mm):

125

Working Base Width (mm):

175

Distance - back to barrel nozzle

(mm):

80

Distance - barrel nozzle to base

- adjustable (mm):

80 - 175

Max. Moulding Area (mm2

)

5000

Electric Motor (HP):

2

Electric Heater (kW):

0.75

Approximate Machine Dimensions (mm):

1500 x 610 x 1500

Approximate Net / Gross Weight (Kg.):

175 / 250

Approximate Shipping Volume (m3

):

1.40

VIDEO

VIDEO OF 40-HM INJECTION

MOULDING MACHINE

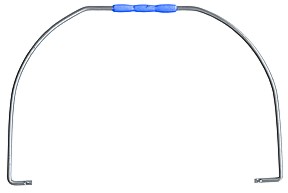

OK (Hook Ends) Type Bucket Handles

OK (Hook Ends) Type Bucket Handles

REGULAR (Notches at Ends) Type Bucket Handles

REGULAR (Notches at Ends) Type Bucket Handles

Loose Type Plastic Grips

Loose Type Plastic Grips

Fixed Type Plastic Grips

Fixed Type Plastic Grips

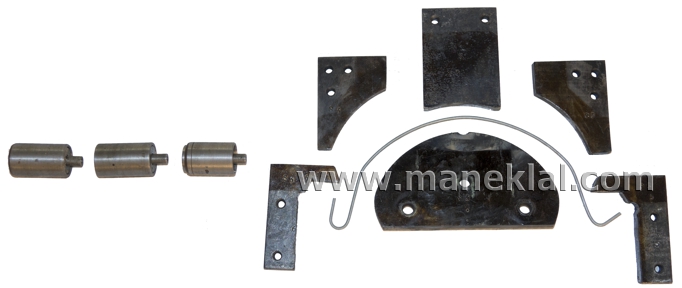

Die of Model: BHM-25EP

Die of Model: BHM-25EP

System to insert Plastic Grips on Model BHM-25EP

System to insert Plastic Grips on Model BHM-25EP

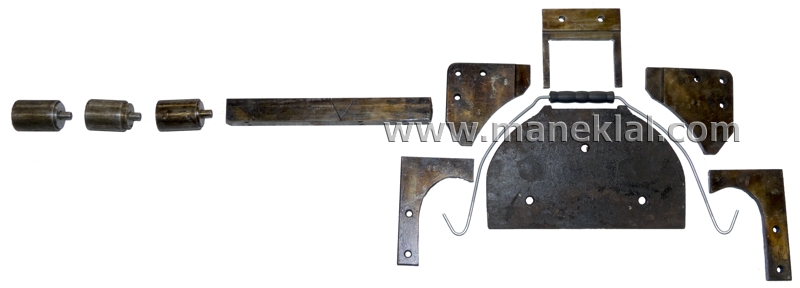

Die of Model:

BHM-10R

Die of Model:

BHM-10R

Model: BHM-10R - For Handle Type Regular (Notches at Ends)

Model: BHM-10R - For Handle Type Regular (Notches at Ends)

PLC Control Panel

PLC Control Panel

Model: 40HM

Model: 40HM

Die for fixing Plastic Grips

Die for fixing Plastic Grips