Angle Board / Edge Board / Safe Corner Making Machines

Manufacturing Process Flow:

- Loading of Paper Strip Rolls

- Mounting on Rolls

- Application of Adhesive

- Scraping of Adhesive

- Pasting Through Rollers

- Forming of Angle Board

- In-Line Cutting at Desired Length

- Optional - Cutting 'V' slots on Angle Board

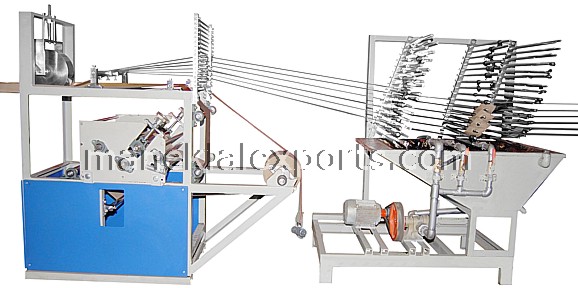

Pre-Forming and Forming Machine

Pre-Forming and Forming Machine

In-Line Cutting Machine

In-Line Cutting Machine

Cascade Gluing System, Outer Layer Forming & Pasting by Roller

Cascade Gluing System, Outer Layer Forming & Pasting by Roller

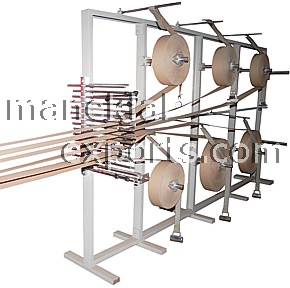

Reel Stand

Reel Stand

Specifications:

| Model: | ABM-4 | ABM-4/HS | ABM-6 |

|---|---|---|---|

| Production Capacity: | 15 to 20 meters / minute | 30 to 45 meters / minute | 10 to 15 meters / minute |

| Thickness of Angle Board: | 3 mm to 8 mm | 3 mm to 8 mm | 3 mm to 8 mm |

| Paper: | Recycled | Bamboo Paper / Non-Recycled | Recycled / Bamboo Paper / Non-Recycled |

| Min. Size of Angle Board: | 25 x 25 mm (1" x 1") | 25 x 25 mm (1" x 1") | 25 x 25 mm (1" x 1") |

| Max. Size of Angle Board: | 100 x 100 mm (4" x 4") | 100 x 100 mm (4" x 4") | 150 x 150 mm (6" x 6") |

| No. of Layers: | 16 Layers | 16 Layers | 16 Layers |

| Max. strip width for inner layers: | 200 mm | 200 mm | 300 mm |

| Max. strip width for outer layer: | 430 mm | 430 mm | 630 mm |

| POWER REQUIREMENT | |||

| Cascade Gluing System: | 2 x 1.0 HP + 2 kW Heater | 2 x 1.0 HP + 2 kW Heater | 2 x 1.0 HP + 2 kW Heater |

| Pre-Forming Machine: | 2.0 HP | 2.0 HP | 2.0 HP |

| Forming Machine: | 4.5 HP | 4.5 HP | 6.0 HP |

| In-Line Cutting Machine: | 0.5 HP | 0.5 HP | 0.5 HP |

| Shipment: | In 40 feet FCL container | In 40 feet FCL container | In 40 feet FCL container |

VIDEO OF ANGLE BOARD MAKING MACHINE MODEL: ABM-4

VIDEO OF WRAP AROUND PUNCHING MACHINE

VIDEO OF SLITTING REWINDING MACHINE

VIDEO OF WRAP AROUND PUNCHING MACHINE

VIDEO OF SLITTING REWINDING MACHINE

Pre-Forming / Pasting of Layers of Paper and Outer Layer Pasting

Pre-Forming / Pasting of Layers of Paper and Outer Layer Pasting

Pre-Forming / Pasting of Layers of Paper and Outer Layer Pasting

Pre-Forming / Pasting of Layers of Paper and Outer Layer Pasting

Control Panel

Control Panel

Control Panel

Control Panel

Gluing System

Gluing System

Outer Layer Unit

Outer Layer Unit

Optional Auxiliary Equipment:

Slitting Rewinding Machine: It is used to slit the paper to the required width. Supplied with unwinding shafts for easy loading and unloading. Paper draw roller, tensioning arrangement, centrifugal clutch and pulley drive arrangement provides tight winding after slitting

Slitting Rewinding Machine

Slitting Rewinding Machine

Slitting Rewinding Machine

Slitting Rewinding Machine

| Model: | MSRM-1100 |

|---|---|

| Maximum Width of Roll: | 1100 mm |

| Slitting Capacity: | 6 Metric Tons of Paper per 8 hours shift |

| Paper Thickness Range: | 60 GSM to 600 GSM |

| Minimum Slitting Width: | 30 mm |

| Drive: | 7.5 HP motor with AC Drive for variable speed |

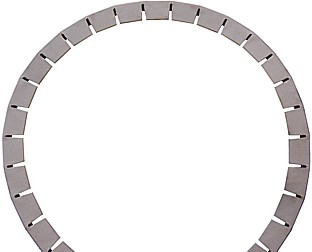

Wrap Around Punching Machine: This machine cuts slots on the formed Angle Board so that the Angle Board can be folded to make round shape. A die is fitted into a 10 Ton Power press. Supplied with 1 HP motor.

Wrap Around Punching Machine

Wrap Around Punching Machine

Compressor: Reciprocating Air Compressor with 10 HP motor

Process of Manufacturing the Angle Board

- Load the paper strips on the reel stand as per the required size of the paper angle.

- The paper, mounted on rollers and rods, moves toward the Glue Stand.

- At the Glue Stand, adhesive is applied to the paper strips using a pump.

- Excess glue is removed from the paper strips using scraping knives.

- The scraped glue returns to the gluing tank.

- The paper strips are pasted onto each other under a roller.

- The gummed strips are passed through forming rollers to shape them into angles.

- The Angle Board is cut to the desired length using an In-Line Cutting Machine.

- Optional: A Power Press can be used to cut slots into the Angle Board for use with round items like drums.

Raw Materials Used for Angle Board

- Semi Kraft Paper: 120 GSM to 180 GSM, BF 16/24

- Kraft Board Paper: 200 GSM to 500 GSM, BF 14/16

- Grey Board Paper: 200 GSM to 500 GSM, BF 14/16

- Virgin Kraft Paper: 150 GSM to 200 GSM, BF 18/30

Manpower Required

- 1 Main Operator

- 1 Power Press Operator

- 1 Helper

Forming Rollers

Forming Rollers

In-Line Cutting Machine Blade

In-Line Cutting Machine Blade

'\__/' Channel Type Angle Board with Optional

Tooling

'\__/' Channel Type Angle Board with Optional

Tooling