Universal Sheet Nibbling Machines / Sheet Metal Nibbler

Features:

- Suitable for small batch production jobs in lieu of big blanking dies and punches

- Useful for Sheet Metal Fabrication Industry, Electric Control Panel Makers, Cabs and Vehicle body makers, automobile fabrication manufacturers, etc.

- Length of tool stroke easily adjusted on variable steps

- Different operations need different tools

- The upper and bottom tools are changed in operation of beading, folding, flanging and punching

- The working principle of the nibbling machine is that the sheet is cut or formed between the fast reciprocating motion of the upper tool (powered by an electric motor and driven by an eccentric crank) and a stationery lower tool, by progressive punching as the sheet is fed.

Specifications:

| Model: | GN-3 | GN-5 | GN-8 |

|---|---|---|---|

| Throat Depth (mm): | 900 | 1000 | 1250 |

| Max. circle diameter capacity from square blanks (mm): | 740 | 830 | 1000 |

| Length of stroke (mm): | 1 - 8 | 1.5 - 9 | 2 - 10 |

| No. of strokes per minute: | 1440 | 1440 | 720 / 1440 |

| Max. tool lift (mm): | 15 | 15 | 25 |

| Motor (HP) | 2 | 3 | 5 |

| Net / Gross Weight (Kgs.): | 700 / 900 | 1250 / 1500 | 2200 / 2500 |

| Overall dimensions (m): | 1.8 x 1.6 x 0.5 | 2.0 x 1.6 x 0.5 | 2.8 x 2.0 x 0.6 |

| Shipping Volume (m3 ): | 1.5 | 1.6 | 3.4 |

Machine Capacity (Sheet Thickness)*:

| Model: | GN-3 | GN-5 | GN-8 | |

|---|---|---|---|---|

| Shearing / Straight Cutting | from the edge (mm): | 3.2 | 5.0 | 8.0 |

| inside with starting hole (mm): | 3.2 | 5.0 | 8.0 | |

| sheet without starting hole (mm): | 2.5 | 4.0 | 6.0 | |

| Nibbling | from the edge (mm): | 2.5 | 4.0 | 6.0 |

| inside with starting hole (mm): | 2.5 | 4.0 | 6.0 | |

| sheet without starting hole (mm): | 2.0 | 3.0 | 4.0 | |

| Rectangular Notching | sheet thickness / width of notch (mm): | 2.0 / 8.0 | 3.0 / 10.0 | 4.0 / 12.0 |

| Figure Cutting | sheet thickness (mm): | 2.0 | 3.0 | 5.0 |

| Slot Cutting | sheet thickness / width of slot (mm): | 2.5 / 8.0 | 4.0 / 10.0 | 5.0 / 10.0 |

| Louver Cutting | sheet thickness (mm): | 2.25 | 3.0 | 4.0 |

| Beading | sheet thickness / depth of bead (mm): | 2.0 / 4.0 | 2.5 / 5.0 | 3.0 / 6.0 |

| Folding | sheet thickness / depth of fold (mm): | 2.0 / 6.0 | 2.5 / 8.0 | 3.0 / 10.0 |

| Flanging | sheet thickness / height of flange (mm): | 2.0 / 8.0 | 3.0 / 12.0 | 3.0 / 15.0 |

| Dishing / Peening | sheet thickness (mm): | 2.0 | 2.5 | 3.0 |

| Punching | sheet thickness (mm): | 1.5 | 2.5 | 3.0 |

| Circle Cutting (Outside / Inside) | sheet thickness (mm): | 2.0 | 3.0 | 5.0 |

*- NOTE: The thickness capacity is for mild steel 45 kg / mm2

Standard Accessories:

- Two slides for attachment mounting

- Set of tool holders with figure cutting bits

- Electric motor

- Push button starter with over-load trip

- Set of operating keys

- Set of operating spanners

- Filler gauge

Optional Accessories:

- Anti-vibration pads

- Hand pushed straight feeding attachment

- Circle cutting attachment (Inside / Outside)

- Nibbling tool

- Louver cutting tool

- Beading tool

- Rectangular notching tool

- Dishing tool

- Flanging tool

- Slot cutting tool

- Punching tool

- Folding tool

- Ball top table

VIDEO SHOWING NIBBLING MACHINE MODEL: GN-5 IN VARIOUS OPERATIONS

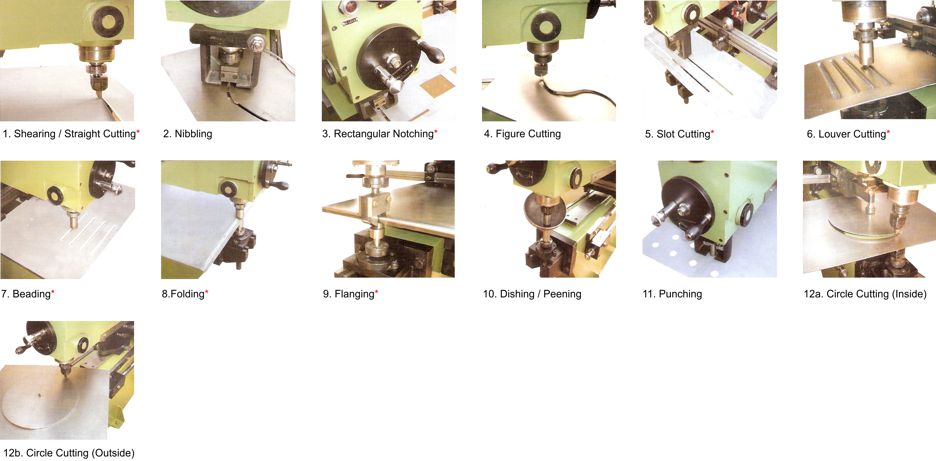

Operations:

* - Hand pushed straight feeding attachment is necessary for these

operations.

All tools except set of tool holders with figure cutting bits are

optional.

- Shearing: Tools are available for straight cutting, figure cutting (contour cutting), and circle cutting operations. The shearing length per cut is small and there is no wastage of materials.

- Nibbling: A continuous punching operation with a circular tool used for producing internal and external cut-outs of any shape. The work-piece does not warp but the edges may require some filing. The fixed nibbling tool is a solid punch cutting at one side. Punch and die clearance is provided to suit the sheet thickness; feed is controlled by tool design.

- Rectangular Notching: A continuous punching operation with a square punch and die, mainly for producing internal rectangular cut-outs. The tool cuts in two directions, producing clean edges.

- Figure Cutting: Can be done with both round nibbling die punch and shearing tools. A quick and economical way to produce parts or cut-outs of any shape and size.

- Slot Cutting: Performed with a double-edge cutting tool, which avoids warping of sheets. Suitable for parting sheets, cutting small strips and slots. The upper tool is changed for each slot width; the bottom tool is adjustable.

- Louver Cutting: A combined shearing and forming operation. The sheet is first cut, then the louver is formed. Length of louvers is independent. Beading, folding, and flanging are also completed in 2–3 passes, with further tool feeding done via hand wheel after each pass.

- Beading: A forming operation used for stiffening (providing strength) of sheets.

- Folding: A forming operation; by double folding, channels can be made for housing electrical wiring, etc.

- Flanging: A forming operation commonly used on sheet metal parts. 0° to 90° flanging is possible by changing the lower tool. 2–3 passes are generally required and intermediate annealing may be necessary to achieve the correct flange angle.

- Dishing or Peening: A mechanical hammering operation used for forming dished parts like tank bottoms. The quality depends on the skill of the operator.

- Punching: Possible with special punch and die sets. Round and square holes (e.g., for fixing lamps or push buttons on panels) can be produced by providing a shear on the punch.

- Circle Cutting (Inside): Attachment capable of cutting small holes from 100 mm diameter up to 75% of the throat depth of the machine.

- Circle Cutting (Outside): Attachment capable of cutting large circles. Centre punch mark is needed for sheet thickness up to 2 mm. Centre locating hole of 5 mm is required for thickness above 2 mm.