Hand Operated Concrete & Pavement Block Making Machine

Features:

- Stand Type versatile machine that could be shifted to any working site to cast blocks on wooden or steel pallets

- Top pressing ram operated by toggle mechanism. Bottom plate is vibrated with light weight adjustable amplitude eccentric vibrator resulting in less voids and higher strength

- By operating the lever, the blocks are left on the pallet

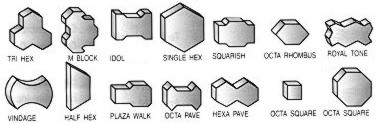

- Any shape of interlocking pavement blocks can be produced in different colours

Specfications:

| Model: | PVB-250 |

|---|---|

| Vibrations: | 6000 Hz Amplitude Adjustable |

| Moulding Area: | 350 x 750 mm maximum |

| Max. size of Block: | 700 x 500 x 300 mm |

| Capacity: |

250 to 300 strokes per shift of 8

hours 200 x 200 x 400 mm (8"): 1 block / stroke - 250 to 400 per shift 150 x 200 x 400 mm (6"): 1 block / stroke - 250 to 400 per shift 100 x 200 x 400 mm (4"): 2 block / stroke - 600 to 800 per shift Interlocking Pavers: 750 to 900 blocks per shift |

| Bottom Vibrator Motor: | 1.5 HP x 2 motors |

| Top Vibrator Motor: | 1.5 HP - The motors driving vibrators are hinged in the frame to give free movement to the table |

| Weight: | 400 kg. |

| Dimensions: | 1.5 x 1.3 x 2.2 m |

| Shipping Volume | 4.5 m3 |

Standard Accessories:

- Electric motors

Optional Accessories:

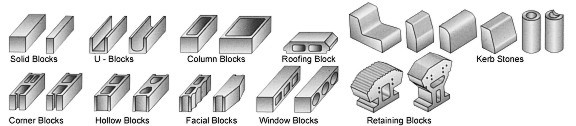

- Sets of ram and mould for making hollow blocks, solid blocks, corner blocks, U-blocks, column blocks, facial blocks, roofing blocks, retaining blocks, window blocks, kerb stones, and pavement blocks of different types

VIDEO OF THE HAND OPERATED BLOCK MAKING MACHINE PVB-250

|

|

|

Pavement Block Moulds |

|

Pavement Blocks

Pavement Blocks

Concrete Blocks

Concrete Blocks

Auxiliary Equipment: Vibrating earth rammer with 5 HP diesel engine for laying blocks, Hydraulic block cutting machine

Vibrating Earth Rammer

Vibrating Earth Rammer

Hydraulic Block Cutting Machine

Hydraulic Block Cutting Machine